Automatic Epoxy Resin Potting Machine Two-component Coating Mixing Machine 10: 1/ab Glue Filling Machine

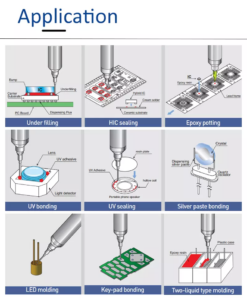

two-component resin automatic metering/mixing/dispensing machine. This system is using servo motors, high-precision metering valves and PLC control mode and this is specially designed for low and medium viscosity resins. (such as epoxies, urethanes, silicones and acrylics) Our system is suitable for potting of abrasive and high-viscosity materials in PCB, Electric parts, Motors, EV motors, LED and others applications. We specialize in providing solutions for high viscosity materials supplying.

Strong versatility / Multiple configuration / High production capacity / High precision

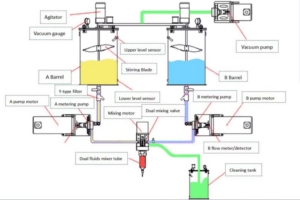

* Auto feeding :take use of vacuum pressure to feed materials into A&B tank separately.

* Tank Stirring :A and B tank configure with stirring motors and blades to prevent material sediment in the tank bottom .

* Heating : Tank , pipe , pumps are optional with heaters to assure the whole system can be heating from room temperature to 90°C adjustable.

* Vacuum : A &B tank vacuum for degas the bubble inside material .

* Dynamic mixing : Configuring dynamic motor and mixer to mix A and B fluids evenly.

2.High precision valve: high speed, glue off clean, no glue drawing, no dropping.

3. Core metering pump specially design for different material from low to high viscosities.

4. Mix glue A & B more evenly; no more or no less for agent B.

Working principle :

Compound materials A & B are kept in two tanks separately. There are two sets of metering pumps inside the machine for metering A and B resin by setting ratio, draining out material individually from tank A & B. Liquid A & B mix with each other in the mixer pipe and dispensed out according to the programmable data.

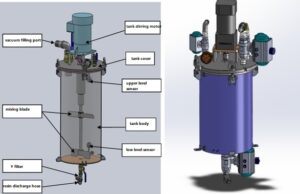

Tank system technology:

2. Tank with motor stirrer that prevent the glue from sediment and keep the potting material in constant temperature.

4 Tank with vacuum degas (degas time can be set through touch screen), so the material can be re-feeding through vacuum negative pressure .

5 Tank with pressure releasing ball valve ; the bottom of tank reserved back-flow connector and river closure ball valve.

6 Tank with heater which can preheat materials to assure good flowability .

7 Tank with artificial feeding mouth that can be added glue appropriately by hand .

8 Tank with silica-dryer which can prevent material especially PU from crystallization

Self-Cleaning:

1. The cleaningswitch points to "air" and uses compressed air to discharge most of the mixturein the mixing tube;

2. The cleaningswitch points to "liquid". If there is a dynamic mixing motor, turn on the dynamic mixing motor before changing the clean switch;

3. After cleaning, the cleaning switch points to "air" and usescompressed air to clear the cleaning liquid in the mixed tube;

4. The cleaning switch points to the middle positiononce finished.

Our Pump-Gear Pump

Our pump- Screw pump

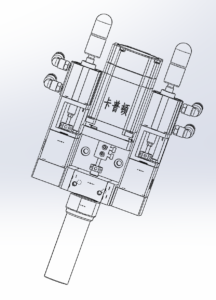

Our mixing valve

Other Sucessful cases :

2. Dispensing&Dosing: LED strip , led lamp , led bulb , aluminum,led screen , display module ,medical parts,medical liquid

filling ....

3. Bonding&doming: LCD screen ,LOCA bonding,ABS plastic,different types of stickers , badge , keychains , souvenirs ,arts , photo frame , and other arts graphics....

Our machine solutions suitable for all kinds of epoxies , pu ,epoxies fluids for different application , anyindustials products

that needs to apply fluids can use our machine to get good performance .