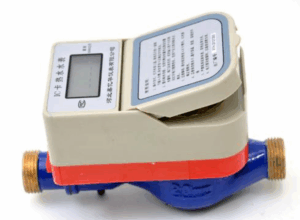

Glue Potting Machine for Water Meter reader

Water meters, as metering and monitoring devices, are exposed to humid, temperature-fluctuating, and complex outdoor environments for extended periods. The potting process is primarily used to achieve waterproof sealing, moisture and dust protection, insulation protection, and fixation of internal components, directly impacting the water meter's lifespan and metering stability.

In terms of process characteristics, water meters have a relatively compact internal structure, with electronic modules and mechanical structures coexisting. The potting area is often a localized encapsulation, requiring high precision in glue volume control and flowability. Epoxy or polyurethane adhesives are commonly used. Products are typically mass-produced, demanding high consistency, stability, and long-term reliability in potting.

Production challenges mainly lie in the high sealing requirements, the susceptibility to air bubbles, uneven glue volume, and glue overflow affecting assembly. Manual potting makes it difficult to guarantee consistency.

The Kapudun potting machine, relying on high-precision metering pumps and dual-liquid valve core technologies, achieves accurate quantitative and stable continuous glue dispensing, effectively improving the sealing quality and production efficiency of water meter potting, meeting the needs of large-scale, automated production

The Core Value of Water Meter Encapsulation and the Technological Empowerment of Encapsulation Machines

In smart city water management systems, smart water meters, as key terminals for data collection and transmission, constantly face complex operating conditions such as damp underground wells, drastic temperature differences between day and night, and mechanical vibration. The water meter encapsulation process and the application of specialized encapsulation machines provide core guarantees for the stable operation of smart water meters from both protective performance and production efficiency perspectives, becoming an important support for the high-quality development of the industry.

Water Meter Encapsulation: Building a Solid Environmental Protection Barrier for Smart Water Meters

The encapsulation process involves injecting specialized potting compound into the electronic modules and key components of the water meter. After curing, it forms a dense protective layer. Its core benefits lie in multi-dimensional protection and performance optimization, precisely solving the environmental adaptability challenges of smart water meters.

I. Ultimate Sealing Protection, Blocking Environmental Corrosion

Waterproofing and moisture resistance are the core values of encapsulation. Precision components inside smart water meters, such as metering chips and wireless transmission modules, are extremely sensitive to moisture. Moisture infiltration can easily cause short circuits, data corruption, or even component burnout. Polyurethane and silicone potting compounds, after curing, form a non-porous elastic adhesive layer with excellent adhesion to substrates such as ABS plastic shells and copper terminals. They completely block the intrusion paths of rainwater, condensate, dust, and chemical substances from pipes. Some high-end potting compounds can achieve an IP68 waterproof rating, ensuring the water meter continues to operate normally after deep-water immersion tests. Simultaneously, the adhesive layer effectively slows down component oxidation and corrosion, extending the water meter's lifespan to 3-5 years or more.

II. Electrical Insulation and Stress Buffering for Enhanced Operational Accuracy

The potting compound possesses excellent electrical insulation properties, with a volume resistivity of 10¹⁴~10¹⁶ Ω・cm and a breakdown voltage of no less than 20kV/mm. It effectively isolates the risk of leakage between circuit nodes, adapting to the "low voltage, high accuracy" electrical characteristics of smart water meters and avoiding metering errors caused by insulation failure. Compared to traditional rigid epoxy adhesives, polyurethane and silicone potting compounds have low curing shrinkage (<3%) and good flexibility, which can buffer internal stress during the curing process and temperature deformation stress during use, preventing damage to precision components such as micro sensors and pins. They also reduce electromagnetic interference and ensure stable signal transmission.

III. Weather Resistance and Safety/Environmental Protection, Suitable for Diverse Scenarios

High-quality potting compounds can achieve a wide temperature resistance range of -40℃ to 130℃, without becoming brittle at low temperatures or sagging at high temperatures, adapting to harsh northern climates, scorching southern climates, and cyclical day-night temperature differences. Regarding safety and environmental protection, mainstream potting compounds comply with RoHS and REACH standards, with no heavy metal or harmful VOC releases. Some products also have UL94 V-0 flame retardancy, meeting environmental requirements for civilian products while reducing safety hazards. For scenarios requiring repair, silicone potting compounds retain elasticity after curing, allowing for easy disassembly and replacement of components, solving the pain point of difficult repair with rigid potting compounds.

Water Meter Glue Dispensing Machine: Automation Upgrades Enable Efficient Production

With the increasing demand for large-scale production of smart water meters, the problems of inaccurate mixing ratios, uneven mixing, and low efficiency associated with manual glue dispensing are becoming increasingly prominent. Water meter glue dispensing machines, with their precise control and automation capabilities, have become key equipment in the production process.

I. Core Working Principle: Precise Control of the Entire Glue Dispensing Process

Water meter glue dispensing machines are specifically designed for two-component adhesives (polyurethane, silicone, epoxy resin, etc.). They achieve standardized operation through a closed-loop process of "glue preparation-mixing-dispensing-cleaning." The equipment receives instructions from the control system via a high-precision metering pump, delivering A and B adhesives to the mixing system according to a preset ratio. Uniform mixing is achieved through dynamic or static stirring, and then the mixture is dispensed quantitatively and at designated points onto the area of the water meter to be sealed. Some high-end models are equipped with vacuum degassing, barrel heating, and liquid level alarm functions to handle different viscosity adhesives and avoid defects such as air bubbles and insufficient glue volume.

II. Core Advantages: Improved Quality, Efficiency, and Cost Optimization

Automated operation significantly improves production efficiency. One dispensing machine can replace 3-6 workers. The dispensing speed is adjustable from 1-40g/s, with a mixing accuracy of ±1%. The mixing uniformity far surpasses manual labor, effectively ensuring consistent protective performance of batch products. The equipment supports touchscreen parameter settings; dispensing ratios and dispensing volumes can be adjusted with a single click, eliminating the need for complex training. It also achieves "mixing and dispensing simultaneously," dispensing according to demand and avoiding glue waste. For various water meter specifications, the dispensing machine's working radius can reach 1-3 meters. Some models support mobile operation, adapting to flexible production scenarios. It also features an automatic cleaning function, completing the cleaning of the mixing tube within 1 minute, reducing manual maintenance costs.

III. Technological Iteration: Adapting to New Industry Needs

The new generation of water meter dispensing machines is upgrading towards high precision and intelligence. It integrates a Panasonic PLC control system and sensor monitoring modules, enabling real-time monitoring of glue flow, pressure, and mixing status, with automatic alarms in case of abnormalities. For specialized water meters such as ultrasonic water meters and IC card water meters, the equipment can be customized with dispensing paths and parameters to accommodate specific thicknesses, such as 20 mm. Simultaneously, the equipment's compatibility continues to improve, adapting to two-component adhesives with viscosities up to 200,000 mPa·s. A mixing device in the material tank prevents sedimentation, meeting the needs of various dispensing applications.

Synergistic Empowerment: Driving the Upgrading of the Smart Water Meter Industry

The synergistic application of water meter dispensing technology and dispensing machines constructs a dual-protection system of "precise protection + efficient production." The dispensing process solves the stability problem of smart water meters in complex environments, while the dispensing machine, through automation technology, scales up the process advantages. Together, they drive the development of smart water meters towards high reliability and cost-effectiveness. Against the backdrop of accelerated smart city construction, the continuous iteration of dispensing materials and equipment will further contribute to the intelligent and refined upgrading of water management, providing core support for ensuring water supply for residents and the efficient utilization of water resources.

For more please consult with us by email sales@abgluemachine.com Whatsapp+86 134 2516 4065