2 part ab potting machine

KPD-800

Suitable for AB component silicone, epoxy,polyurethane for LED and electronic Potting and Encapsulate

Need a technical advisor to answer your questions?

Whatsapp:+86 134 2516 4065

Email:sales@abgluemachine.com

Machine information:

Mixing ratio :

100:100-100:10 adjustable . Dynamic or static mixing mode are optional .

Tank liquid level sensor :

Tank liquid level alarm helps remind glue level line in tank and supplement materials immediately.

Vacuum filling:

The machine can automatically feeding material by using of the negative pressure of AB vacuum tank .

Vacuum degas :

Vacuum defoaming can remove the bubbles contained in the material,and this degas system can satisfy different fluid mixing and potting .

Heating:

Heating helps glue, especially PU and epoxy, to quickly reduce viscosity in cold weather, increase flow speed, and improve glue

filling efficiency.

Self-cleaning :

Automatic cleaning can quickly clean the mixing tube and prevent the mixture from solidifying

Self-discharging

Automatic discharging can discharge the mixture that is about to be solidified in time to prevent the mixture from solidifying in the mixing tube

| Models | KPD-800 2K mixing and dosing machine |

| Governing equation | Microcontroller + Oscillator |

| Power supply | 220V 50HZ |

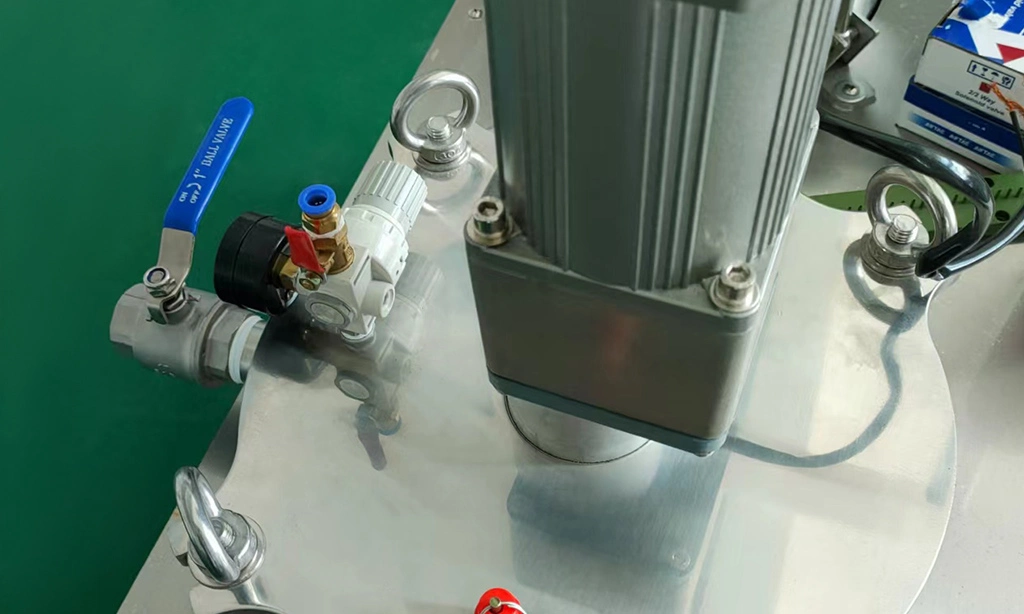

| Pneumatic | 0.5MPa-0.7MPa |

| Equipment power | 850W(Except when heated) |

| Gelatin ratio | 1:1-10:1 selectable |

| Hybrid approach | Static/dynamic (switchable) |

| Measurement method | PLC + precision metering pump |

| Countertop Height | ±2% |

| Gluing speed | 0.5g-15g/sec Adjustable |

| Drum volume | 10L、20L、30L、or customised |

| Overall dimensions | 880*480*1600 |

| Equipment weight | 350KG(reference weight) |

| Delivery function | Vacuum defoaming, automatic gluing, heating device, automatic cleaning, barrel mixing |

Double pusher structure

High speed, quiet and durable

Servo dual pusher structure

Efficient sawing for increased capacity

304 stainless steel high pressure sealed drum

Aesthetically pleasing, pressure resistant and easy to clean

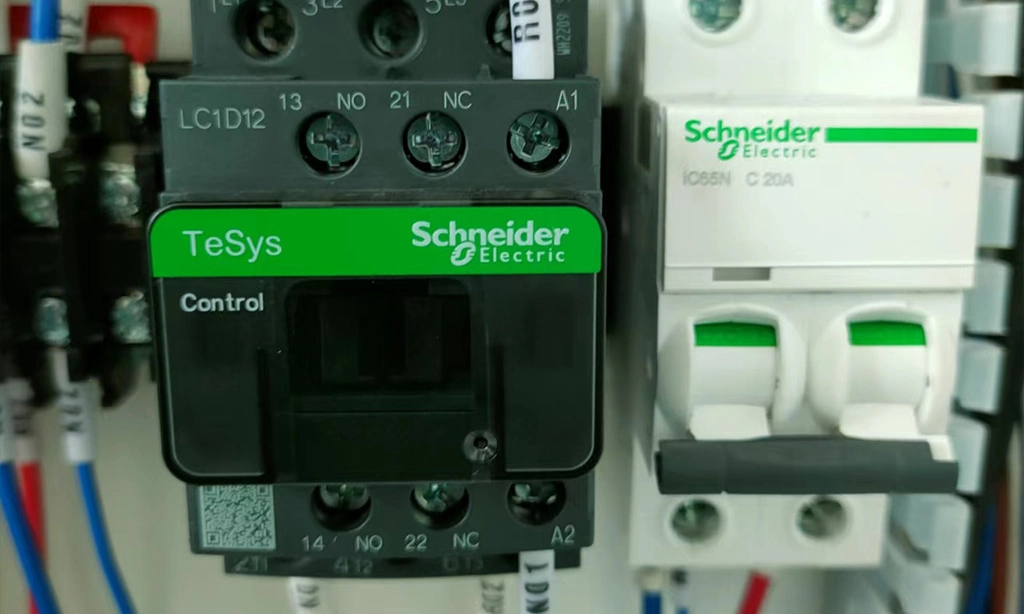

Imported electrical and pneumatic components

Precision and stability

APPLICATIONS

Typical products encapsulated include cable splice, coils, power supplies, sensors, transducers, switches, and control modules.

1)Potting and vacuum encapsulation of electronic/ electrical assemblies, sensors, connectors, coils, and other electroniccomponents.

2) Overmolding of harness breakouts, watertight electrical connectors, cables, cable end seals, and other printed circuitry.

3) Bonding or sealing

Typical products encapsulated include cable splice, coils, power supplies, sensors, transducers, switches, and control modules.

1)Potting and vacuum encapsulation of electronic/ electrical assemblies, sensors, connectors, coils, and other electroniccomponents.

2) Overmolding of harness breakouts, watertight electrical connectors, cables, cable end seals, and other printed circuitry.

3) Bonding or sealing