Sandwich Panel Glue spraying machine KPD-1600

KPD-1600

Automatic identification

Glue heating

Automatic cleaning

Precision Measurement

Need a technical advisor to answer your questions?

Whatsapp:+86 134 2516 4065

Email:sales@abgluemachine.com

1.Automatic edge finding: (automatic recognition) automatically adjusts the glue spraying position according to the size and length of the board;

2. Automatic glue amount: (automatically adjusts the speed of glue dispensing according to the size of the board and the conveying speed);

3. Automatic glue feeding: When the glue volume in the glue barrel is lower than the set lower limit, the glue adding process will be automatically started.

4. One-click start: Eliminate the tedious preparation work before starting up, and realize automatic operation to working status with one click;

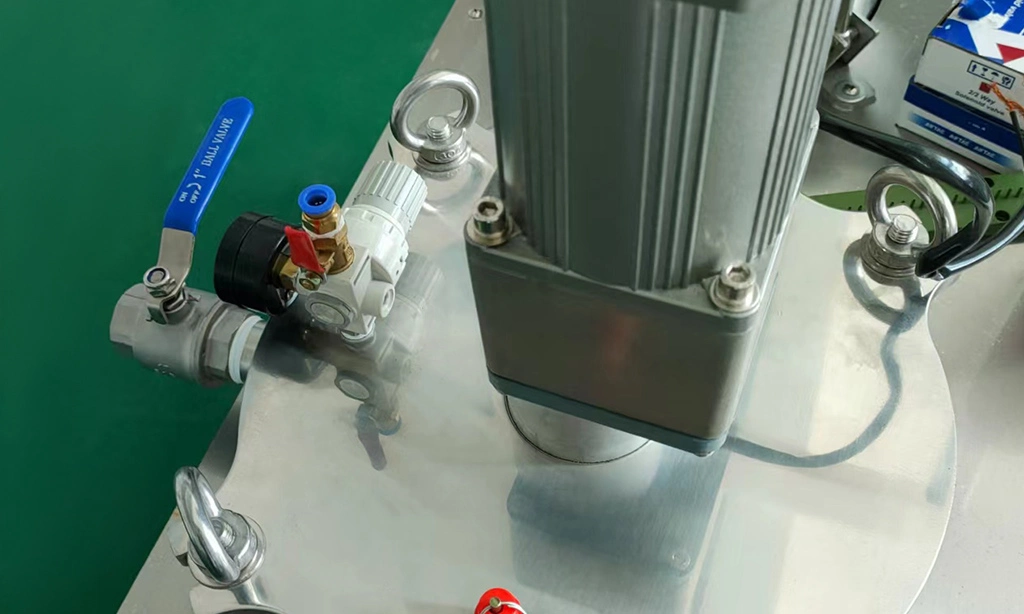

5. Glue heating: The equipment is equipped with glue heating and heat preservation functions, so that the glue is not restricted by ambient temperature and region, allowing customers to choose the brand of glue more freely;

6. Anti-sedimentation mixing: A glue barrel is equipped with an intelligent control mixing device to prevent precipitation or stratification caused by long-term stasis of glue, and to ensure that the glue is heated evenly.

7. Visual mixing: The equipment adopts imported dynamic mixing tubes and is matched with Taiwan's high-speed brushless motor to achieve adjustable mixing speed and direct viewing of the mixing status to ensure uniform mixing;

8.Disassembly-free automatic cleaning: The equipment adopts a high-pressure gas-liquid automatic switching cleaning device. There is no need to disassemble the glue spray head, achieving true disassembly-free cleaning in the industry, and the cleaning effect is visible to the naked eye;

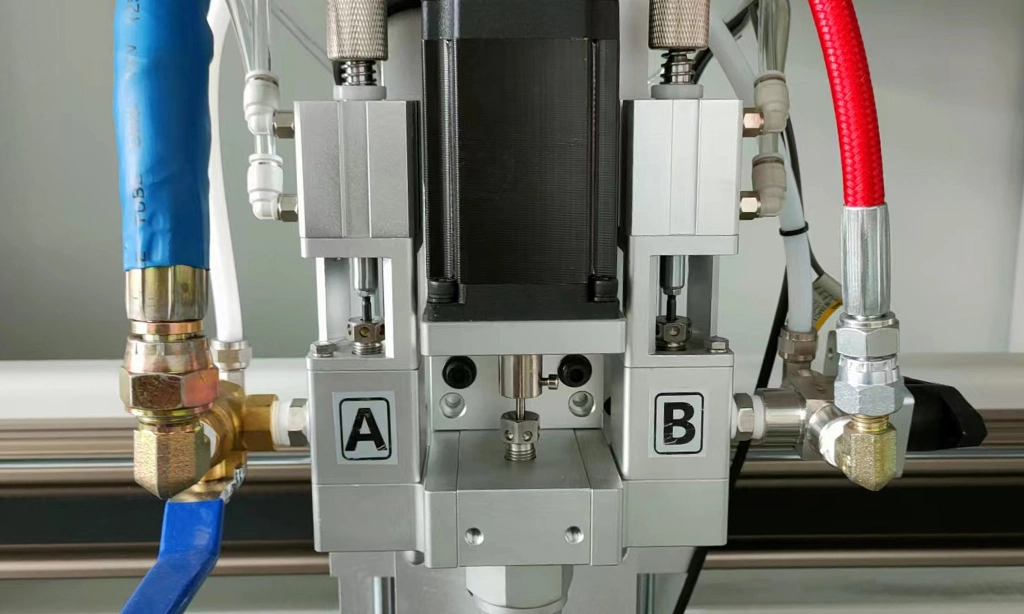

9.Patented glue-controlled suction valve: The equipment is equipped with our company's patented glue-controlled anti-drip suction valve, which can open the glue in time and close the glue quickly with suction adjustment;

10.Special metering pump: The equipment adopts a special polyurethane high-flow and wear-resistant precision metering pump , which can accurately control glue and adjust the flow rate to achieve an accuracy of ±0.5%, effectively avoiding inaccurate proportions and greatly improving the product qualification rate;

| Model | KPD-1600 |

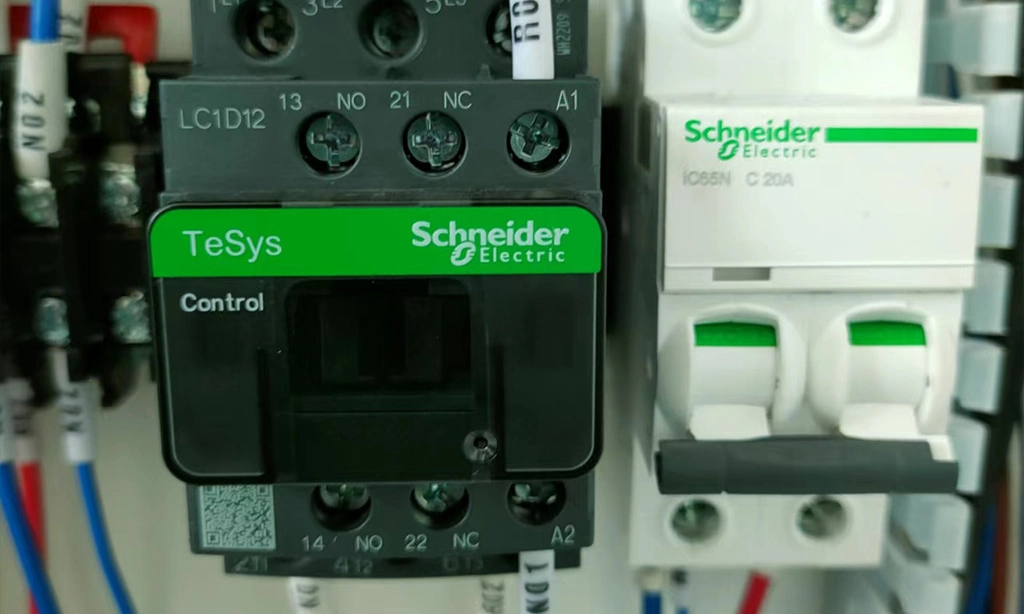

| Governing equation | Velen Touch Screen + Mitsubishi Programmable Controller |

| Power supply | 220V 50HZ |

| Pneumatic | 0.5MPa-0.8MPa |

| Equipment power | 2780W |

| Countertop Height | 800MM±50 |

| hybrid approach | High speed dynamic mixing 100-3000 rpm |

| Measurement method | Industrial computer + Mitsubishi PLC + precision metering pump + precision glue control valve |

| Proportioning accuracy | 100g±1% |

| Gluing speed | 0.5g-40g/sec |

| Overall dimensions | 9000-2250*1750 (rated according to model) |

| Equipment weight | 1000KG(reference weight) |

Patented split glue control valve

High speed mixing, instant glue cutting, no dripping

High-quality motion components

High speed, quiet and durable

304 stainless steel high pressure sealed drum

Aesthetically pleasing, pressure resistant and easy to clean

Imported electrical and pneumatic components

Precision and stability

XPS EPS sandwich panel , honeycomb panel , insulation panel, Composte snawich panel,Mgo borad, Clean room panel and so on